As part of our unrivalled customer service here at HTL Group, we provide full and comprehensive service & testing of controlled bolting equipment to ensure that your tools always remain in safe working order.

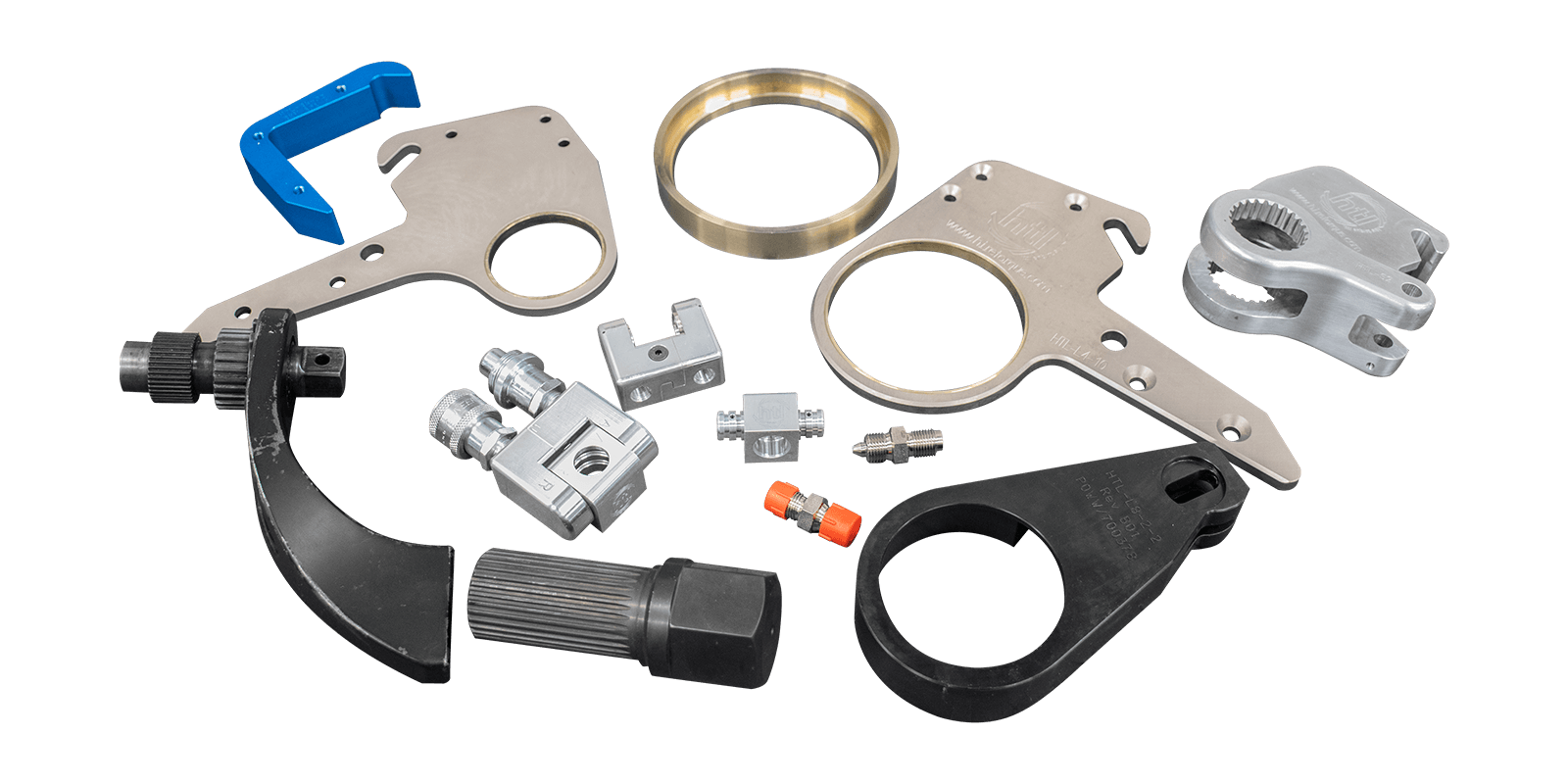

Our qualified engineers are on hand 24/7 for the service, repair and maintenance of a wide range of controlled bolting equipment. This includes, but is not limited to:

We also offer a complete range of services to ensure that your equipment, whether purchased from ourselves or another supplier, remains in safe working order. This includes us providing you with a full in-date certification, to allow for total traceability using our i-calibrate.com service.

So whether you require a simple hydraulic oil change or a total equipment rebuild, our dedicated service and testing team are on hand to assist.

We stock a comprehensive range of spare parts as well, ensuring a rapid turnaround of time-critical equipment. We are happy to quote costs on an ‘item by item’ basis, but are equally satisfied with providing a scheduled service plan with fixed costs on certain items over a 12-month period.