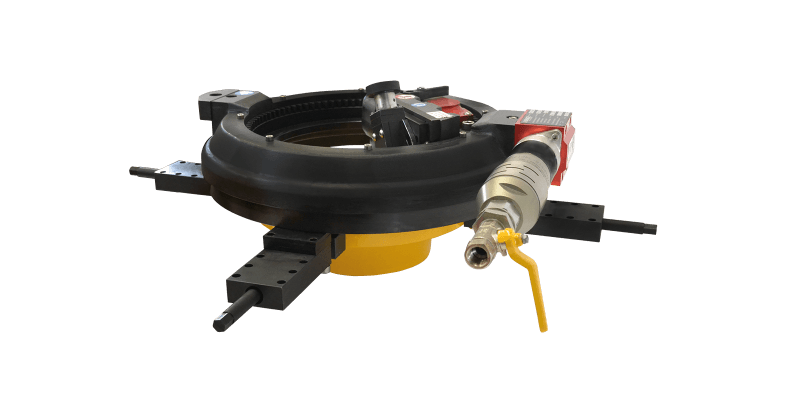

Enerpac MM300e (0mm – 305mm )

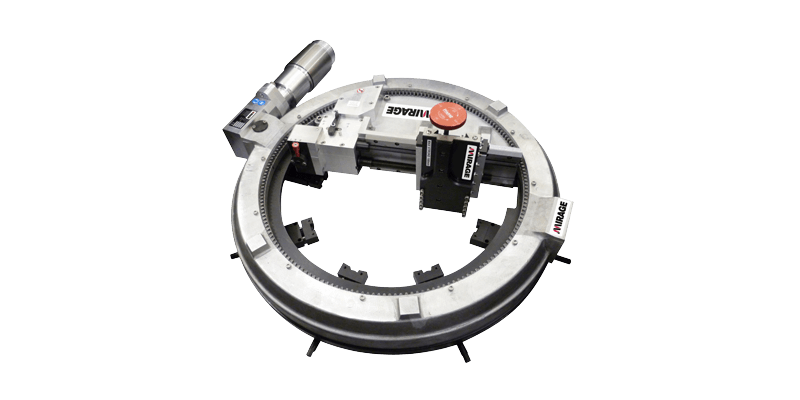

The Enerpac range of internal and external mounting flange facing machines offer unparalleled performance with the range

containing the most reliable, durable, efficient and precise flange facing machines on the market. The innovative design

incorporates the latest linear and ball screw technology, utilising the patented 360 degree powered tool posts allowing the

operator to control these machines at ease reducing operational risks. All flange facing machines are delivered ready for use

for standard flanges and seal groove configuration with an independent locking base. The Enerpac flange facing machines can

be used for a wide range of applications including rise face flanges, RTJ grooves, heat exchanger flanges, techlok flanges,

recessed gaskets and spigots, weld preps, hub profiles, lens ring joints & SPO compact flanges.

The MM300e model is an externally mounted flange facing machine suitable for all types of flanges, seal grooves, weld preps

and counter bores. The MM300e machine is supplied complete with toolkit including tools and inserts, air filter lubricator and

hose connection, all required mounting feet and extensions, storage / shipping box, CE certificate, packing list and manual.

Features and Benefits

- Lightweight, precision built to optimise on-site performance

- Fast set 4 jaw base for reduced set-up time

- Helical gear drive for improved surface finish

- Swivel tool post for wide range of applications

- High accuracy, preloaded cross roller drive ensuring robust, repeatable machining

- Geared continuous groove facing feeds for gramophone finish

- (ASME Standard)