Controlled bolting is the process for correctly applying a known load to a mechanical joint to ensure it’s joint integrity.

As bolted joints are often one of the most common elements in industrial components, the reliability of each joint is of the utmost importance. The physics that explain fastening devices for bolting are well known, and over the years, we’ve developed accurate means of measuring and applying force to joints consistently.

When it comes to bolted joints, the significance of the bolted connection is often the contributing factor in deciding the importance of its joint integrity. Pressure vessels and pipe flanges require leak-free fittings to ensure their safe operation, and the machinery industry needs to guard against vibrations. More casual applications, such as the attachment of fascias or covers to equipment, may only need to be manually tightened to perform their required tasks.

For joint integrity operations, controlled bolting is very important, with bolt load accuracy being the primary focus. This method of tightening fasteners ensures that both the tightening and loosening of bolts is carried out in a controlled and safe manner. Therefore, controlled bolting is used to either secure the integrity of the joint or safeguard against damage to it during disassembly.

Applying torque or tension forces to mechanical connections are the two most commonly used approaches used to tighten a bolt. Torque tightening utilises the helix of the bolt thread to guide the nut down the bolt threads, which in turn applies a bolt load. This is usually carried out using hydraulic torque wrenches. Whereas Tensioning applies a direct tensile (stretching) load to the bolt avoiding the torsional (twisting) reaction forces associated with torque.

There are several benefits to using a controlled bolting method, not only does it increase efficiency across industries where time constraints are typical, utilising measured torque and tension techniques maintain safety standards and ensure that these standards are kept consistent.

The consistency of bolted joints is crucial when dealing with joint integrity as any inconsistencies can alter or damage a bolting operation, resulting in catastrophic disasters. Using calibrated controlled bolting tools and accredited techniques provide reassurance that each bolted connection is correct and to a known value each time, eliminating the risk of errors.

Industry recognised training standards, such as those provided by the ECITB, have been developed to ensure that operators and technicians around the world are competent in safely operating the equipment without compromising the integrity of the joint. In the untrained, human errors can affect joint integrity during the stages of assembly, tightening and loosening. Therefore, using Controlled Bolting methods can lead to a ‘right-first-time’ approach to the management and integrity of the bolted joint.

Following tragic events that have occurred in the oil and gas industry over recent decades, the health and safety standards have significantly improved and are now tightly regulated.

Companies should now offer additional resources for employees such as accredited training and improved technological knowledge to ensure standards are maintained and consistency across all controlled bolting operations.

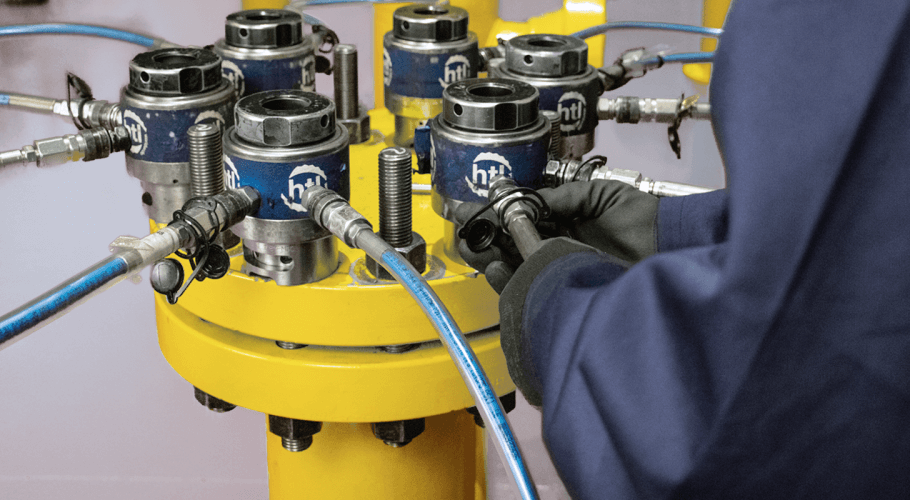

HTL Group has lead the way in being bolting product specialists, offering Torque and Tension tools that are designed to provide the most innovative bolting tools on the market. As the industry demands efficiency and safety, the Group also provides a complete suite of accredited training for mechanical joint integrity. Achieving a true combination of the right tool and skill set for Controlled Bolting activities.