We look forward to continuing to provide you with our impeccable Customer Service and technical support, along with our premium quality, UK Made controlled bolting equipment. 2019 gave us new opportunities with product launches and continued growth. With our positive outlook for 2020, HTL are here to support you in all of your controlled bolting […]

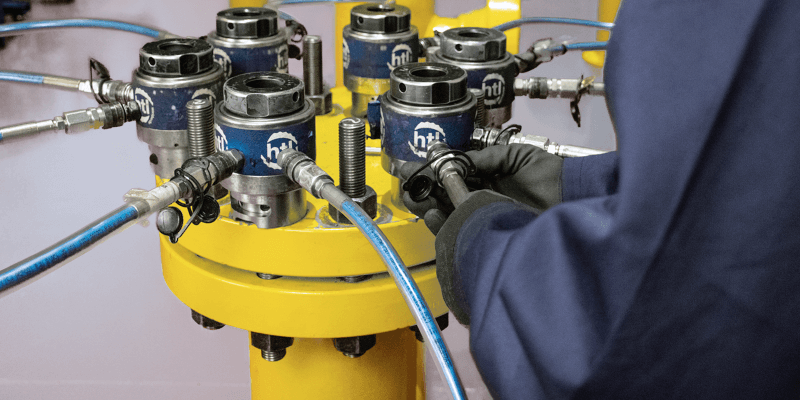

Controlled bolting is the process for correctly applying a known load to a mechanical joint to ensure it’s joint integrity. As bolted joints are often one of the most common elements in industrial components, the reliability of each joint is of the utmost importance. The physics that explain fastening devices for bolting are well known, […]

The HTL staff in their Christmas jumpers and fancy dress, in support of our nominated charity Jessica’s Sarcoma Awareness who help children and teenagers battling Cancer.

After a great Offshore Europe show this year, we’d like to thank everyone who visited the HTL Group stand. It was a pleasure meeting you, we hope you enjoyed this year’s show and discovering HTL’s product and service portfolio. Didn’t attend? Call us on +44 (0) 1670 700 000, or email info@htlgroup.com to discuss your requirements.

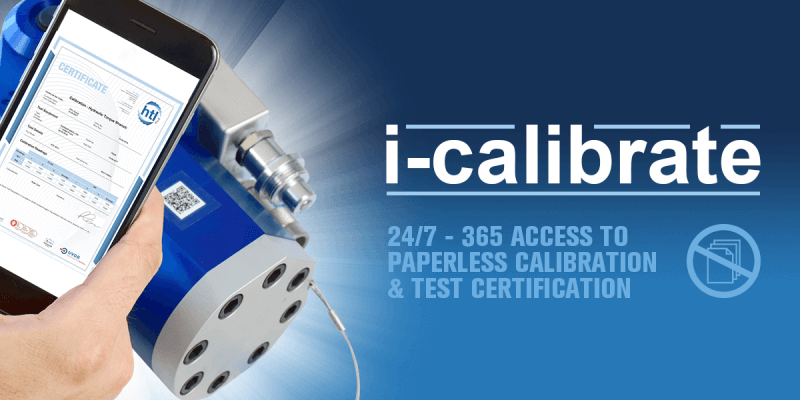

Real-time, paperless calibration; i-calibrate. HTL Group will launch their new certification software at this year’s Offshore Europe. Offering complete traceability, i-calibrate provides real-time access to equipment certification via a PC or any smart device using QR codes.

Global training providers HTL Group and Safety Technology have collaborated to provide industry with an even greater portfolio of courses. HTL Group are renowned for their ever growing controlled bolting equipment range and their suite of technical courses including ECITB approved Mechanical Joint Integrity training and testing covering MJI 10, 18, 19, 21, 22, 30, […]

HTL Group, global OEM of controlled bolting and fluid power solutions return to this year’s SPE Offshore Europe at stand 1F45. Showcasing a range of innovative new products, HTL’s friendly team look forward to welcoming visitors to their stand to discuss and demonstrate these latest innovations. Following the relocation and launch of the group’s ‘HTL […]

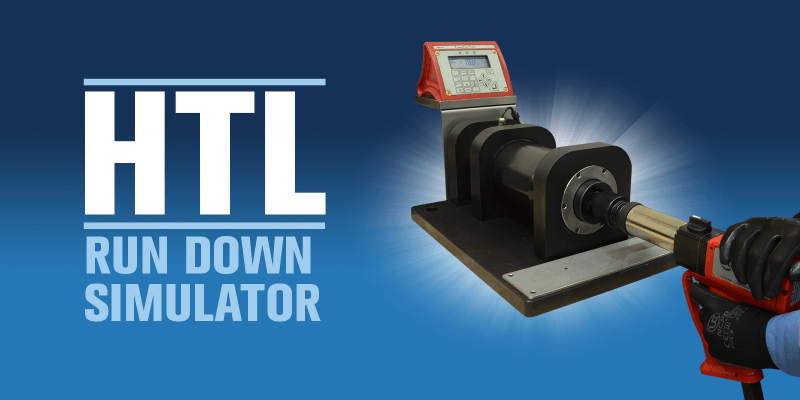

The HTL Run Down Simulator is designed to calibrate and test continuous rotation torque tools. Supplied with a Norbar digital torque display and transducer, calibrated to UKAS standards, the Run Down Simulator has an operating range of 500-5000 Lbf.ft / 678-6789 Nm. With a simple design, the Run Down Simulator accepts all common brands of […]

HTL Group are taking on a new cycling challenge ; the HTL 100, to raise money for their adopted charity, Jessica’s Sarcoma Awareness. The 2 day challenge will see participants cover a distance of 100 miles through the rolling roads of Northumberland. The challenge begins at HTL’s Headquarters in Cramlington, and finishes at Alnwick on […]

Our Calibration Van is a mobile solution which ensures torque tooling can be calibrated direct on-site, saving costly downtime. The HTL Expo Unit brings everything HTL direct onsite to you, allowing for our ever growing portfolio of products and services to be showcased directly at your premises, ensuring minimum disruption. To discuss your requirements and […]